Condition Monitoring

Beaver Electrical Provides Preventative, Predictive, And Reliability Based Maintenance And Repair For AC Motors And Generators.

![]() Download our Predictive and Preventative Maintenance datapack

Download our Predictive and Preventative Maintenance datapack

Preventive maintenance (PM) and predictive maintenance (PDM) are familiar terms, but the tasks associated with these methods of maintaining and extending the operating life of electric motors and generators aren't always clear. Beaver provides a complete set of strategies all under the umbrella of reliability-based maintenance (RBM).

Preventive Maintenance (PM).

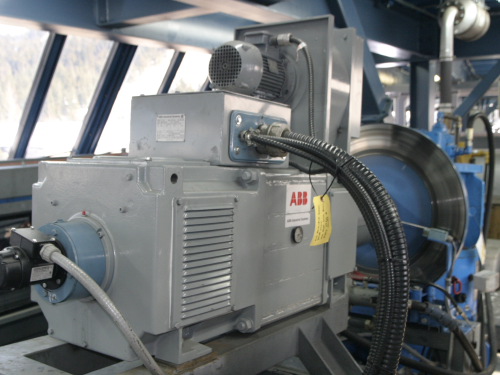

The primary goal of PM is to assess motor health through inspections and tests. For example, the condition of a winding is determined by the megohm value from an insulation resistance (IR) test. Electrical tests typically include measuring IR (with motor shut down) and individual phase voltages and currents (during normal operation). Mechanical assessments in a PM program usually include vibration analysis (FFT spectra) and alignment.

Other PM activities commonly include cleaning and inspection; lubrication and lubricant level checks; and adjustment of belt tension and bolt tightness. Thermal scanning with an infrared camera is also common. Noise levels can be assessed subjectively or with acoustical analysis equipment.

Predictive Maintenance (PdM).

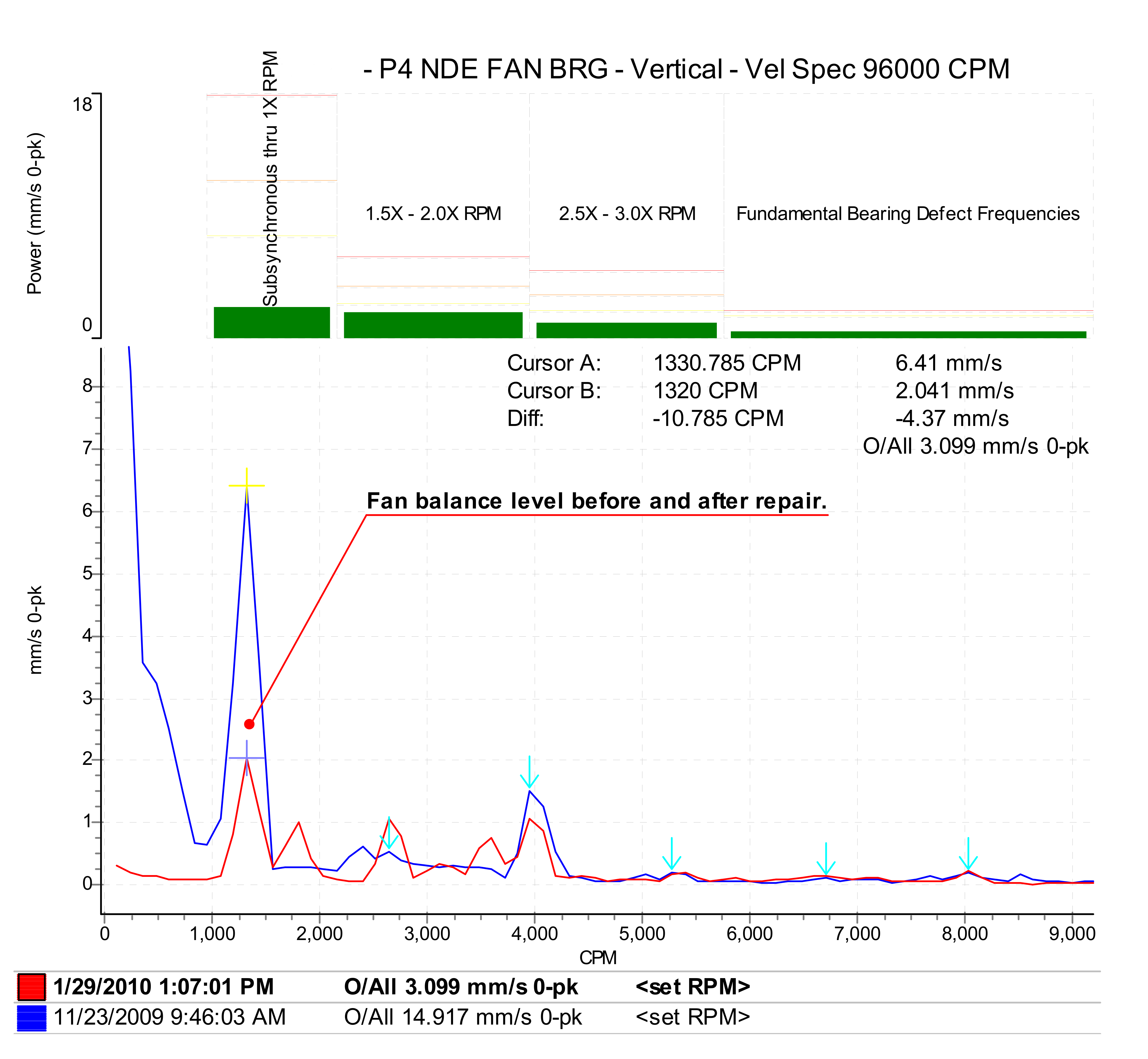

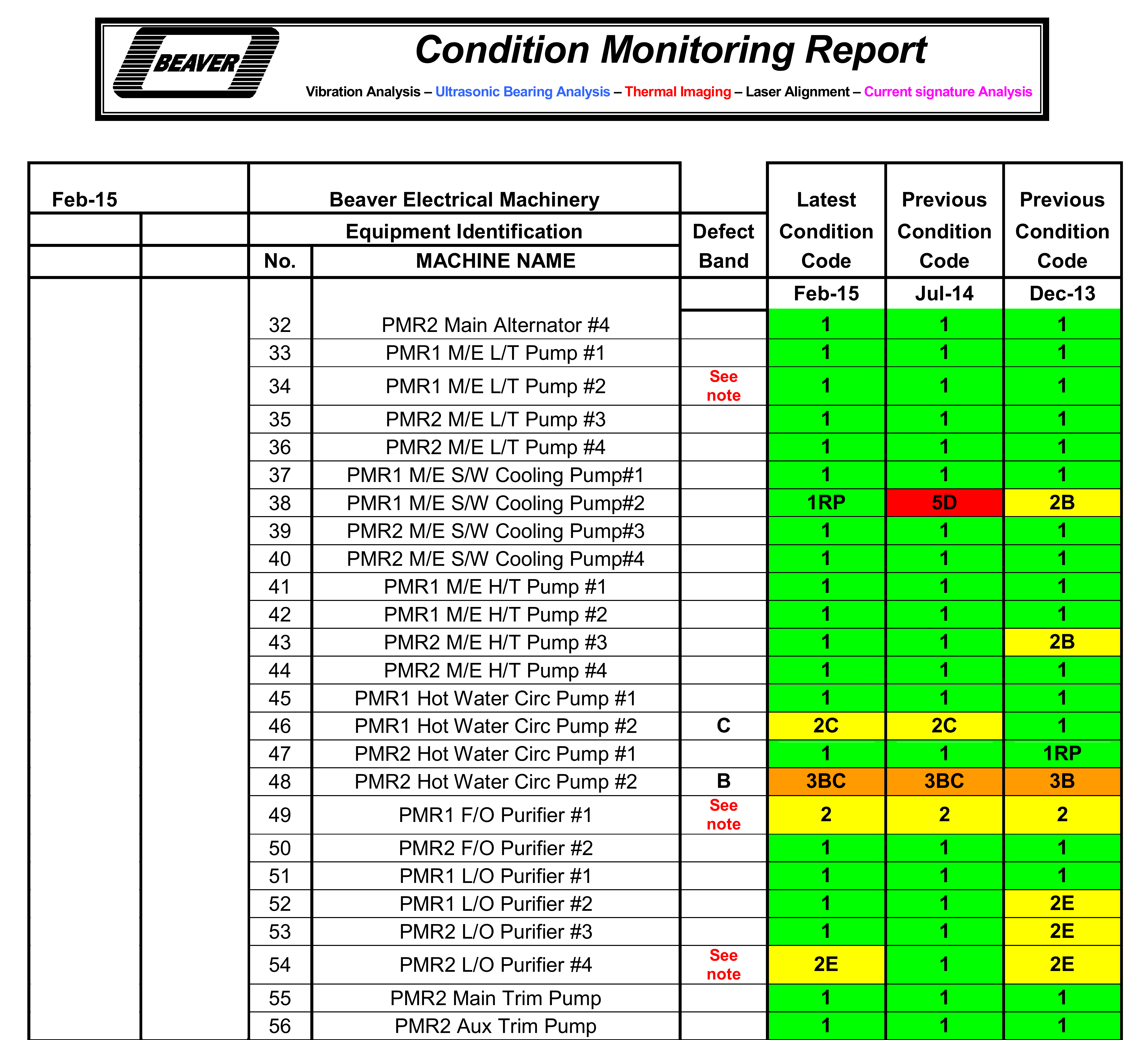

Predictive maintenance forecasts when to perform corrective maintenance, or when to expect a failure. Also called condition monitoring, PdM consists of trending and assessing most of the activities associated with PM. PDM usually trends electrical activities like IR and polarization index (PI) tests and sometimes motor circuit parameters, current and voltage levels, and MCSA results. Trending of mechanical routines normally includes the vibration spectra and occasionally thermal scan test results. As an example, if the megohm value of the winding insulation was initially acceptable but trending lower, that trend can be used to schedule corrective maintenance before the IR value drops dangerously low, or to predict when it will be too low to operate the motor safely.

Reliability-Based Maintenance (RBM).

RBM, also called reliability-centered maintenance (RCM), is a method for determining the best combination of maintenance activities to enhance equipment reliability and safe operation. These include cleaning and lubrication as well as repair or replacement of failed components. Reliability expresses the probability that a motor will perform properly for a specified time, under stated conditions. RBM reduces maintenance to the most cost-effective activities, so it requires understanding of motor failure characteristics, manifestations, and consequences.

What is the alternative? Run to failure.

Running to failure is the oldest philosophy and requires the least amount of expense until a problem actually occurs. This type of maintenance can only be justified if:

- The machine has no importance to continuing production.

- All machine parts are readily available and inexpensive.

- Scheduling downtime for maintenance may occur at any time.

Rarely does a machine meet all of these criteria. Another major drawback of this type of maintenance plan is that a catastrophic failure cannot be predicted. A catastrophic failure could be dangerous. Repairs may be lengthy, expensive, or impossible.

|

|

| Example data of a dataset comparing motor running conditions before and after balancing and repair. | Example meta-report of a facility-wide condition monitoring program. Reporting draws attention to equipment requiring attention. |