DC Motor Rewind & Service

DC Motors provide some unique benefits over AC motors in certain applications in industry. A maintenance program prolongs the life expectancy of your DC motors and is an effective way to prevent unscheduled downtime.

> The Beaver Team offers comprehensive support and testing capabilities 24 hours a day, 7 days a week. <

VIBRATION ANALYSIS AND ALIGNMENT

Vibration analysis is a critical part of the testing process to insure that the DC Motor and equipment attached are safe for operation and will ensure the reliability and longevity of bearing and equipment life expectancy.

SHAFT CURRENTS

DC electric motors connected to a DC drive could potentially see damaging shaft currents causing bearing failures. The shaft currents are caused by common mode voltages that can discharge through the bearing. This can cause electrical discharge machining (EDM), pitting, frosting, and fluting damage. Damage to the bearings can result in unplanned downtime and costly repairs. Installation of insulated bearings and grounding brushes or rings are designed to eliminate shaft currents.

BRUSH INSPECTION

Brush inspection is one of the most critical inspections you can do to insure the reliability of a DC motor. Checking for brush wear, seating, brush spring tension and proper grade as per manufacture specifications. This will help enhance the longevity of your brush life, overheating of brushes, commutator wear, brush sparking and possible flashovers.

RESISTANCE TEST

The resistance test is the first check to see if your armature windings are shorted. Our MA2 Analyzer can be used to check the resistance of the windings and the armature. If the resistance drastically varies, there could be a problem with the windings. A drop in resistance could indicate a short between conductors in the coil. A huge spike in resistance could indicate that a conductor is open, interrupting the circuit.

INSULATION (MEGGER) TEST

It is important to check that none of the electrical circuit’s insulation has deteriorated and have gone to ground creating a short circuit damaging windings, connected equipment, and creating a potential shock hazard.

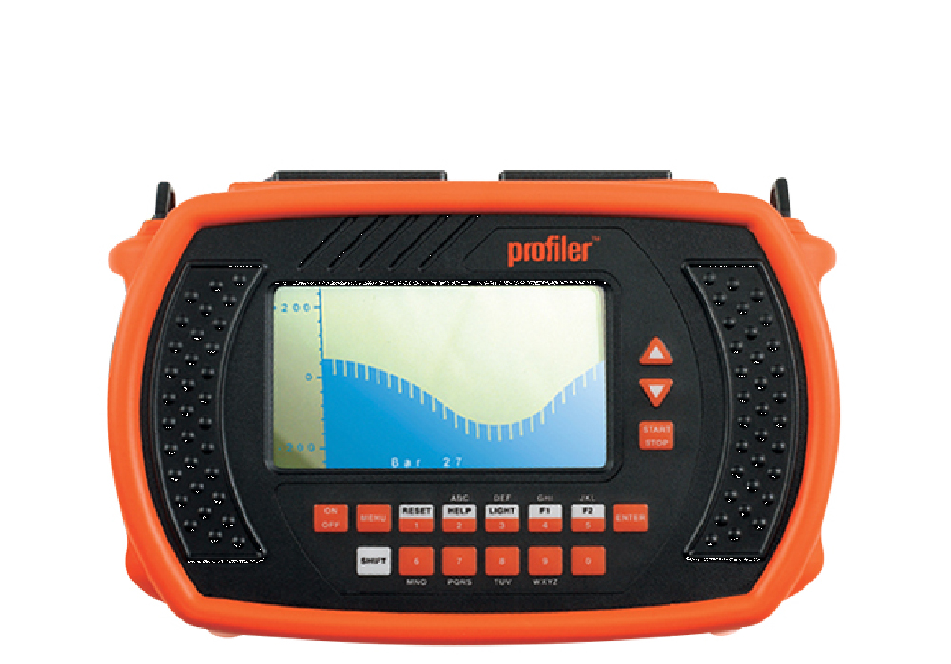

BAR-TO-BAR TESTING

Bar to bar testing checks every coil in the motor armature to determine that the coil resistance is within manufacturer specifications. This will ensure there are no shorted, grounded, or damaged coils or commutator bars. Our MA2 analyzer with special cabling is used for this test.

COMMUTATOR PROFILING

Comm profiling checks the concentricity of the commutator and the consistency of the wear of the commutator bars. Regular scheduled commutator profiling service can help maintain minimal arcing and destructive sparking to increase your carbon brush life. Prioritizing these goals, will help ensure that your DC motor performs reliably for the long term.

VOLTAGE DROP TEST

The voltage drop test is among the quickest, easiest, and most valuable; allowing for easy evaluation of the quality and efficiency of your circuit’s operation. A voltage drop test can be readily performed with a basic load and a digital voltmeter (DVM). Once the load is applied, the DVM can measure the live connection for a voltage drop in the circuit under load. An indication of voltage drop can be an early warning sign that cleaning, maintenance, or routine repairs are needed.

NEUTRAL TEST

Properly setting the brush rigging as close to neutral under 10mV as close to 0mV of DC motors will help prevent brush wear, arcing and potential flashovers. Our MA2 analyzer with special cabling is used for this test.

VERY LOW FREQUENCY (VLF) TEST

We now have the means to Hipot high capacitance coils or long HV cables in the field. Using our HVA45TD instrument is safe and efficient to perform a low frequency AC high voltage test. Applying basic physics, the lower the frequency of a voltage applied to a capacitance, like a motor winding or shielded HV cable; the lower the mA’s of current, hence power, is required to charge a load to the desired test voltage. At 60 Hz, the time from 0 to peak voltage is 4.2 ms. At 0.1 Hz the time to max voltage is 2.5 seconds. With 600 times longer to charge the load at 0.1 Hz, 600 times less current is needed. It means that AC Withstand, or proof/hipot, and diagnostic testing requiring a high voltage AC source, are now field practical and should be performed where necessary. DC high voltage testing is not a substitute for AC in most cases and should be avoided.