A Look at Electromagnet Repair

Posted by Jacek Laszkiewicz on May 29, 2023

Electromagnets have a wide range of applications, serving as crucial components in many industries. Our team at Beaver Electrical specializes in electromagnet repairs, with a focus on coil rewinding and restoration. We aim to share insights from a recent repair we carried out for a mining client.

|

|

|

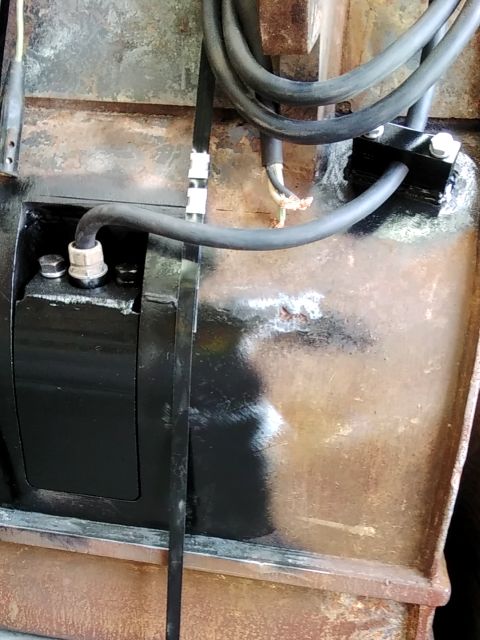

| The repaired magnetic bucket | Supporting bracket and cable gland |

Repairing a 'Bucket Magnet'

The task involved a 'bucket magnet' with a rating of 230 Vdc, 8.6 ohms coil. This electromagnet was specifically designed for mining operations.

Accessing the Coil

The process started by creating access to the coil. This was accomplished by plasma cutting the bottom plate, a procedure carried out with precision to ensure the magnet's structure remained intact.

Coil Re-potting and Restoration

Once we accessed the coil, it was re-potted. This process involves covering the coil with a protective resin, which provides insulation and shields it from environmental elements. After the re-potting, we welded the bottom plate back into place.

Junction Box & Cable/Coil Termination

The next step involved the junction box, an essential component in electrical systems. We plasma cut it off to gain access to the cable and coil termination. After access was gained, a new cabtire cable was installed to ensure a robust and durable connection.

Extending and Re-potting the Coil/Cable Termination

To improve the coil and cable termination, we extended the pipe/cable shroud, which allowed for additional re-potting at the termination. Once this step was completed, we energized the electromagnet with a 230VDC, resulting in a magnetic draw of 27.3 amps.

|

|

|

| Poor condition of cable exit before repair | Exposed magnetic coil before re-potting |

Final Assembly

Finally, we welded the junction box back onto the electromagnet and created a new cable holder. This holder was then welded to the bucket, providing a secure setup.

Our team at Beaver Electrical has a track record of reliable electromagnet repair and rewind services. We understand the importance of these devices in industrial settings and are equipped to provide necessary services to maintain and improve electromagnet performance. If your electromagnets require professional attention, we are prepared to assist.