Rush 2000 KW GE Motor Overhaul

Posted by Jacek Laszkiewicz on Mar 22, 2023

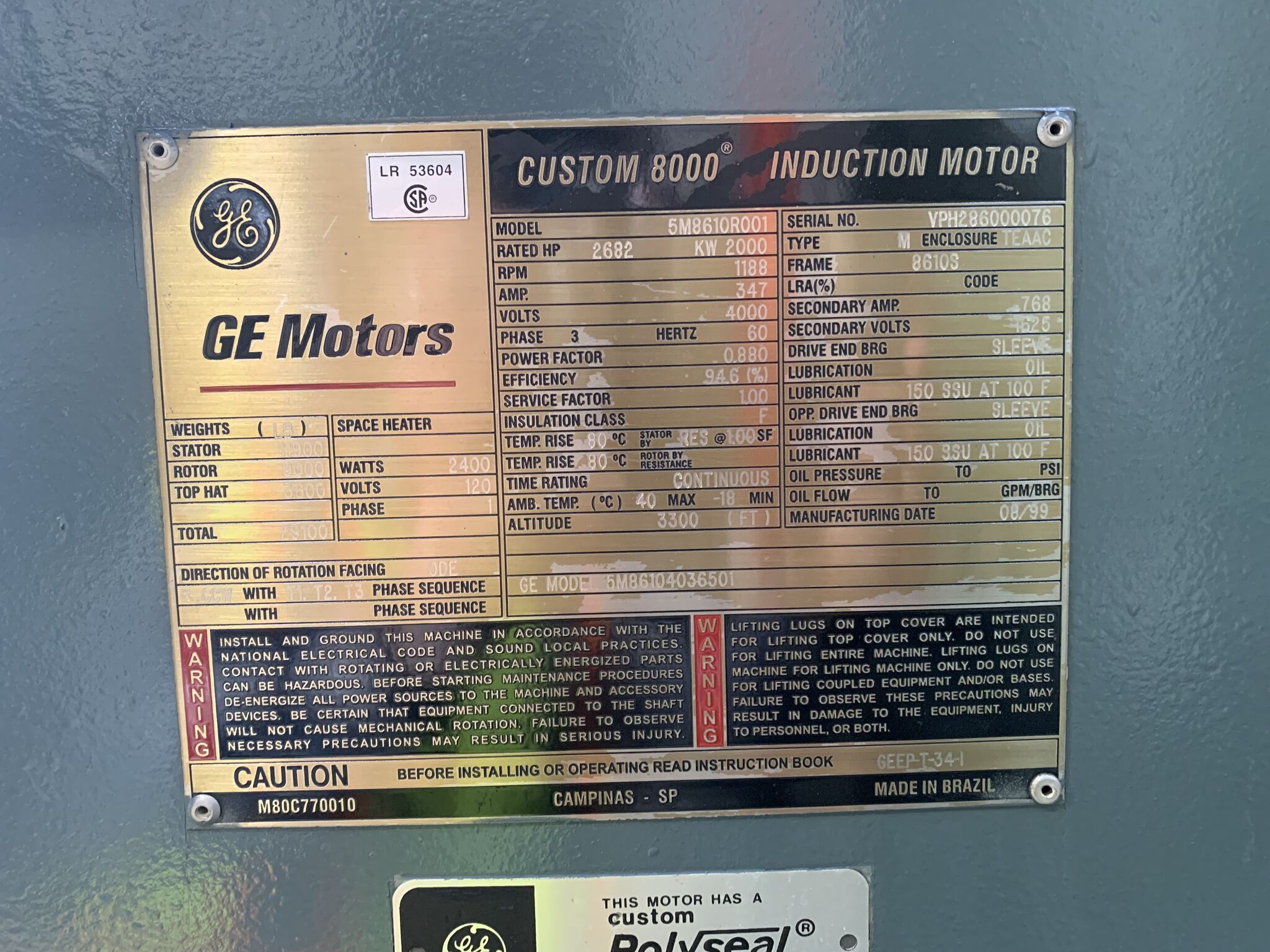

Overhauling a 2682 HP GE Motor: Fixing Overheating & Oil Problems

Our dedicated team worked together to handle an urgent repair job for a large industrial client in the Lower Mainland. The challenge involved a 2682 HP (2000 kW) GE Induction Motor sent to our Beaver Burnaby shop for an overhaul. The main issue was the overheating of the non-drive end bearing.

After a thorough inspection and basic tests, our Beaver technicians identified several problems:

- Inboard labyrinth seal was installed backwards, causing oil to seep into the winding section

- Non-drive and drive end RTDs (Resistance Temperature Detectors) were also installed incorrectly

- Stator frame, winding, and terminal box were filled with oil

- Main rotor leads at shaft exit were swollen due to oil contamination

Once these issues were addressed, the motor successfully passed all tests and was delivered to the customer's site. As part of the overhaul process, our team also performed rotor balancing to ensure optimal motor performance.

Motor Nameplate |

Rotor balancing using an IRD295+ |

||

Pre-repair condition |

Loading onto truck for delivery |

Loading onto truck for delivery |