Doble Testing Available

Posted by Jacek Laszkiewicz on Aug 25, 2022

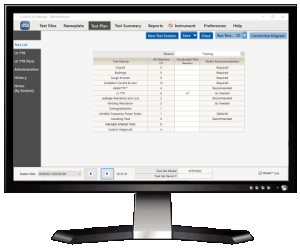

Doble M4100

Beaver Electrical technicians are now trained to use the industry leading Doble M4100 Power Factor/Tan-Delta instrument. Contact us to see how we can be part of your facility's commissioning, diagnostic & scheduled maintenance testing procedures.

The Doble testing technique has proven throughout the years to be an effective diagnostic tool in the power industry. In North America, companies utilizing these testing techniques comprise 80% of the total connected generating capacity.

A deeper dive into Doble:

Scope of Field Testing

Power-factor insulation tests were first made in this country about 1917, by cable manufacturers, for research and control of manufacturing operations. Power-factor tests were first applied to the field testing apparatus insulation about 1929 by the Doble Company. All large manufacturers of bushings make routine power-factor tests on new bushings at their factories; bushings manufacturers' literature recommend odic field power-factor tests and contain typical power-factor data. All ASA standard bushings rated 25kV and above have a power-factor test tap that permits bushing testing without disconnection of windings, etc., from the bushings. Most of the large manufacturers of transformers make routine factory power-factor insulation tests on new power transformers and on oil immersed instrument transformers; the large transformer manufacturers are prepared to make power-factor insulation tests at their factory and are familiar with the advantages of these tests. Thousands of tests have been performed in the field on rotating machinery and cable insulation. Special equipment is available for tests on large rotating machines and on long lengths of cable. Some of the large manufacturers of lightning arresters recommend the routine field use of ac dielectric-loss tests to detect presence of moisture and corrosion in arresters, and mechanical defects such as broken gap shunting resistors. Field power-factor tests on askarel and oil are make to detect the presence of moisture and other contaminants, and to determine whether the condition of the oil is responsible for the high power-factor of the bushings, circuit breakers, transformers, etc.

Advantages of Power Factor Tests

Power-factor insulation test is effective in locating operating hazards in electrical power apparatus, before failure, as it has the following advantages:

- It can detect the presence of "bad" insulation even though there may be a layer of "good" insulation in series with the "bad" insulation; dc tests usually show infinity or high insulation resistance under this condition. Many forms of insulation deterioration involve layers of good and bad insulation in series; for example, sections of insulation of a compound-embedded bushing which have been unevenly exposed to moisture entering through the gaskets or a crack in the water shed.

- It provides a measure of the overall operating condition of the insulation in terms of the ratio (the power-factor of the insulation) which is independent of the amount of insulation being tested; for example, modern, immersed oil, paper insulated power transformers, in good condition, will have a power factor less than 1.0% at 20°C regardless of the make, size and voltage. The power-factor of the insulation increases when the insulation becomes deteriorated; experience has shown the abnormal power-factor values which indicates a failure hazard.

- It provides a measure of overall condition of ac apparatus insulation under simulated normal frequency operating condition which is independent of the duration of the test; dc tests require more time, do not simulate normal insulation operating conditions, except on dc apparatus, and the results are affected by the duration of the tests.

- It provides data for a comprehensive analysis of the nature of insulation deterioration and operating hazards in terms of dielectric watts loss and charging current, at selected test voltages, from which power-factor, capacitance, ac resistance, and the presence of ionization (corona) can be determined. All these measurable characteristics of insulation are used in the routine analysis of field test data.

- It provides data which permit an orderly grading of the serviceability of apparatus insulation by comparison with the correlated results from many thousands of tests and investigations made on similar apparatus insulation, since 1929.

- It provides a more comprehensive picture of the overall operating condition of the insulation than any other single type of test.

Status of Power Factor Tests

The power-factor insulation test is being used for commissioning and routine maintenance testing of the following types of electric apparatus: Bushings (breakers and transformers) Bus supports (one-piece and multi-piece, in place) Cables (in lengths of up to approximately 500 feet - longer lengths require special test equipment) Cable Joints (requires removal of 3" section of lead sheath at both ends of joint) Capacitors (carrier and power-factor correction) Circuit Breakers, Air (insulators, barriers, operating rods) Circuit Breakers, Oil (bushings, lift and guide rods, tank insulation, oil) Hot-Line Tools and Switch Sticks Insulators (suspension, post, pin and stack types) Lightning Arresters (gap and valve units) Liquid Insulation - Oil and Askarels (for presence of moisture and contaminants) Potheads (can be tested without disturbing the cable sheath) Rotating Machinery (large units require special equipment) Transformers, Instrument (bushings, windings, barriers and oil) Transformers, Distribution (bushings, windings, barriers and oil) Transformers, Power (bushings, windings, barriers and oil) Voltage Regulators (bushings, windings and oil).

Test Procedure

Power-factor insulation tests on electrical power apparatus are made with the apparatus out of service. In many cases it is necessary to merely open the disconnect switches to prepare the apparatus for the initial tests. A few tests, made by applying an ac voltage to the conductors of the apparatus in its assembled position and measuring the dielectric losses to ground, will indicate whether or not the insulation is in a normal condition. If the initial test indicates an abnormal condition, the test engineer or technician has a number of special tests which may be applied to localize the deterioration.

Interpretation of Test Data

The interpretation of insulation test data involves the use of elementary principles in the dielectric behaviour of insulating materials and the use of correlated test data, acquired by experience by the Doble Engineering Company since about 1929. In many cases failure hazards of apparatus insulation are expressed in terms of maximum allowable power-factor values; however, changes in the "normal" watt loss, ac resistance and capacitance are also used for indicating hazards in apparatus insulation, depending upon the type of insulation being investigated. Several bushing manufacturers have published factory and operating limits in terms of power-factor. Ver Frequently, abnormal test values obtained during the initial tests are due to the accumulation of carbon deposits or "bad" oil, which may be cleaned up without permanent injury to main insulations. These conditions may however represent serious operating hazards which require immediate attention. the ability of the test to detect this type of operating hazard before a visual inspection is made of the interior of the apparatus, facilitates a more efficient use of maintenance manpower and thus a savings in maintenance costs. Apparatus with deteriorated insulation may sometimes operate for long periods of time without failure, depending upon its exposure to over-voltage and short circuits; however, deteriorated insulation creates a definite operating hazard which should be recognized and corrected if needless interruptions to service are to be eliminated. Deteriorated insulations, if removed before failure, may often be reconditioned and restored to service, with substantial savings in material costs

"Power factor insulation tests" are used to refer to the complete AC dielectric loss tests.

Excerpts from Doble Engineering Company's publication #UOD-1801

How important is Doble testing?

Doble testing is important to determine the condition of a transformer, because it can detect winding and bushing insulation integrity and problems in the winding and core. Doble tests are conducted in the field on de-energized transformers using special test equipment.

What does a Doble test do?

A Doble test is basically a power factor test performed on transformers to ensure they are functioning correctly. This dissipation testing can also be performed on MV cables and motors.

What is a TTR test?

A TTR (transformer turns ratio) test assesses the condition of a transformer's windings and core. Throughout the life of a transformer, TTR results are compared against the nameplate ratings to reveal insulation deterioration, shorted turns, core heating, or other abnormalities.

Where can I rent a Doble test set?

A Doble test must be done by a specially trained technician. Rental of a set by an untrained electrician is inadvisable. Beaver's technicians based in Greater Vancouver can perform testing and write reports on their findings for you and your facility.

What is a power factor test?

A power factor test is a maintenance test used to determine the insulation system dielectric power loss by measuring the power angle between an applied AC voltage and the resultant current. Power factor is defined as the ratio of the power dissipated divided by the input volt-ampere multiplied by 100%.